- Wear and Spare Parts >

- Tillage Parts >

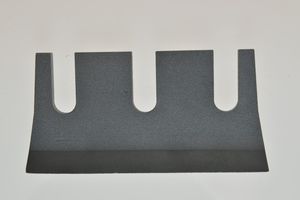

- Harvester knife

Harvester knives

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

compatible for BISO knife60-0170-69-01-0

... corresponding wear behavior of the knives. Surface The flail knife range is offered oiled, or powder coated. The surface sealings ensure the best possible preservation or protection of the flail blade ...

MWS Schneidwerkzeuge GmbH Co. KG

... corresponding wear behavior of the knives. Surface The flail knife range is offered oiled, or powder coated. The surface sealings ensure the best possible preservation or protection of the flail blade ...

MWS Schneidwerkzeuge GmbH Co. KG

... corresponding wear behavior of the knives. Surface The flail knife range is offered oiled, or powder coated. The surface sealings ensure the best possible preservation or protection of the flail blade ...

MWS Schneidwerkzeuge GmbH Co. KG

THE SCHUMACHER STRAW CHOPPER KNIVES A sharp product A straw chopper knife is exposed to particularly high wear at the outer edges of the blade. In this area, the sharp cutting edges ...

Made of Boron steel, blades are high wear resistance. The specific heat-treatment combined with special sharpening process creates a long life bevel with razor sharp edge, for optimal performance and finer cut.

LA PINA Industrias Angel Martinez Lopez, S.L.

The Best Blades in the Business! Redekop has designed blade upgrade kits to work with most major combine brands and models sold in North America. In side-by-side tests, customers are amazed at the ...

... coatings. They protect the teeth on the blade and extend the exploitation period. Sharp knives reduce fuel consumption, which significantly increases the profitability of production. The construction of our knifes ...

UG poland sp. Z o.o

FONTANA, PLC, manufactures knives and cutting parts for wide range of plant harvesters and machines for preparation and processing of fodder crops. Materials used, modern technologies and a team of experienced workers ...

FONTANA, a.s.

... very hard materials. Materials: For the manufacture of knives and shear bars for self-propelled and towed forage harvesters we use steel specially designed to meet the strictest requirements in terms of wear-resistance ...

... and efficiency within the agricultural industry, Forges de Niaux has developed a range of basecutter blades for sugarcane harvesters. These blades attain unequaled levels of hardness (60 HRC) ensuring a perfect cut with ...

The world’s first highly wear-resistant coating of the entire crop flow channel for self-propelled forage harvesters. Advantages of BusaDUR® wear protection coatings: highest service life – depending on the coating ...

Busatis GmbH

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how AgriExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining