- Farm Machinery

- Fertilization

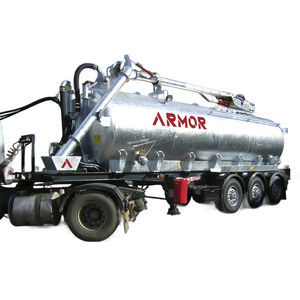

- Drip hose spreader boom

- ARMOR Industries

- Products

- Catalogs

- News & Trends

- Exhibitions

Drip hose spreader boom

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Other characteristics

- drip hose

Description

Umbilical spreading or otherwise called “without ton” is made up of 4 parts:

The pressure pump . Driven by the tractor or by a thermal engine, it offers a flow rate of up to 300m3/h. Priming is carried out by a hydraulically driven vacuum pump or by a thermal engine. Two valves, controlled at the station or remotely, ensure the supply or return to the pit or caisson.

The hose . The hose must be resistant to traction, pressure and friction. The diameter varies depending on the distance. The choice of the type of fitting is important.

The reel . With a capacity of 1000m, it is composed of one or two hydraulic motors. The reels are fixed or detachable.

The ramp or the burier . ARMOR offers a wide range of spreading tools mounted with a traction rod.

12 to 24m pendulum ramp

Pad injector

Toothed buriers

Disc buriers

VIDEO

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Slurry spreader

- Towed slurry spreader

- Vacuum slurry spreader

- Single-axle slurry spreader

- Slurry injector

- Mounted slurry injector

- 3-axle slurry spreader

- Spreading boom

- 2-axle slurry spreader

- Disc harrow slurry injector

- Folding spreading boom

- Drip hose spreading boom

- Tine slurry injector

- Slurry tanker with centrifugal pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.