- Farm Infrastructure

- Storage & Conveying

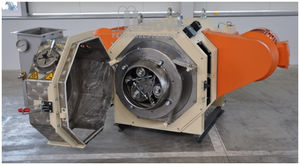

- Grain feed conditioner

- BDW Feedmill Systems GmbH & Co. KG

Grain feed conditioner Salmacon

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Options

- for grain

Description

Conditioners are used for the homogeneous mixing of basic components, controlled adding of additives, such as steam and molasses, and to achieve the desired process temperature. Conditioners are located directly above the pelleting press and, in conjunction with the screw feeder, ensure a continuous flow of optimally processed material.

Pros

•High mixing effect thanks to optimal coordination of paddle arrangement, speed and content

•Sturdy steel housing, made entirely in stainless steel

•Round shaft bulk material in stainless steel

•Mixing paddle made ?of wear-resistant stainless steel, adjustable conveying angle (sojourn time change)

•Full-length inspection opening on the entire mixing chamber with locking hook in assembly

•Special nozzle for separate molasses and addition of steam, molasses nozzle with fan spray insert

•Direct low-noise V-belt drive

•Variable speed

Catalogs

No catalogs are available for this product.

See all of BDW Feedmill Systems GmbH & Co. KG‘s catalogsOther BDW Feedmill Systems GmbH & Co. KG products

Pelleting systems and pellet coolers

Related Searches

- Silo

- Grain silo

- Metal silo

- Inclined elevator

- Mobile elevator

- Hopper silo

- Feed elevator

- Hammer grinding mill

- Steel silo

- Stationary grinding mill

- Bucket elevator

- Animal feed grinding mill

- Sweep auger

- Silo sweep auger

- Vertical bucket elevator

- Tubular sweep auger

- Feed conditioner

- Electric sweep auger

- Grain feed conditioner

- Modular silo

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.