- Products

- Testing machine

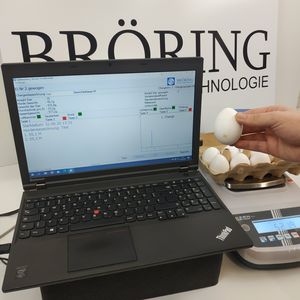

- Bröring Technology GmbH

Impact testing machine Electronic Egg for eggs

Add to favorites

Compare this product

Characteristics

- Applications

- for eggs

- Other caracteristics

- impact

Description

Bröring Electronic Egg:

Whether it's a poultry farm, sorting facility, or packing station: With precise impact detection, smart WiFi data transmission, and incredibly easy operation, you minimize egg damage, save costs, and increase your efficiency. A price-performance ratio that will delight you! Tested and proven: The Bröring Electronic Egg has passed the toughest practical tests: It has proven itself on conveyor belts, sorting machines, and production facilities worldwide. Intuitive, clear, ingenious! No training, no complicated instructions – any operator can master it in minutes. Robust, reliable, and ready for your production! Highlights that will inspire: Pure precision: High-precision sensors with adjustable thresholds detect every impact – for maximum egg safety.

Smart and connected: Real-time data via WiFi for fast analysis and optimization of your systems.

Instantly understandable: Three-color LED displays (green, yellow, red) show weak points at a glance.

Universally applicable: Perfect for poultry farms, sorting plants, and packing stations.

Robust and durable: Compact design for continuous use in demanding environments.

Child's play: Simply position, start, and optimize – no prior knowledge required.

How it works: Simply place the Bröring Electronic Egg on your conveyor belt – like a normal egg. It detects impacts in real time, saves data, and signals problems via clear LED colors. With WiFi, you can access the data immediately, find weak points, and prepare your systems for the future. It couldn't be easier! Your advantages at a glance View: Less breakage, more profit: Precise weak point analysis reduces egg damage and waste.

Catalogs

No catalogs are available for this product.

See all of Bröring Technology GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.