- Farm Infrastructure

- Storage & Conveying

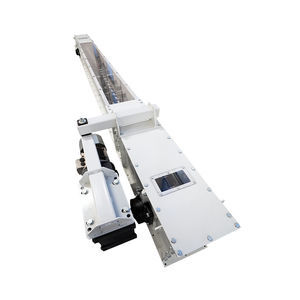

- Nuts conveyor

- MIAL F.lli Massini s.r.l.

Grain conveyor nutsanimal feedpneumatic

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for grain, nuts, animal feed

- Technology

- pneumatic

Description

The Pneumatic Conveyor is particularly suitable for transferring bulk powder or granule products when it is essential to avoid cross-contamination between different products. It is the ideal solution for transferring products over long distances while preventing contamination of the transported materials. Its modular structure allows it to be adapted to various needs and installed in confined spaces. The wide range of models and the possibility of adopting 'Dense Phase' or 'Dilute Phase' technology according to needs allows for use in many sectors, from food to chemicals to animal feed. Using air as a transport medium limits mechanical wear and significantly reduces maintenance compared to traditional systems.

- Transportable products: Malt and cereals, Coffee, Nuts, Pellets, Chemicals, Granuloplastics, Pet food, Animal feed

Characteristics and advantages:

- No contamination of transported product

- Transport using air as a vehicle

- Long transport distance

- Wide range of models

- Modular structure allowing quick on-site installation

- Easy cleaning

- Wide range of accessories for most industrial applications

- Ideal for transferring food products

- High reliability even in heavy-duty applications

- Limited maintenance

Customizable options:

- Piping and accessories in stainless steel 304

- Piping and accessories in stainless steel 316

- Loading hoppers

- Loading systems

- Pneumatic diverters

- Manual and pneumatic valves

- Hose joints

- Discharge hoppers

- Support structures and servomechanisms

- Product storage silos

- ATEX version

- Control panel

Technical specifications:

- Transfer of powder or granule products

- Suitable for long distances

- Possible installation in confined spaces

- Use of air as a transport medium

- Numerous customization options (stainless steel, hoppers, valves, etc.)

Catalogs

No catalogs are available for this product.

See all of MIAL F.lli Massini s.r.l.‘s catalogsRelated Searches

- Tank

- Belt elevator

- Grain elevator

- Plastic tank

- Water transport tank

- Inclined elevator

- Mobile elevator

- Screw elevator

- Polyethylene reservoir

- Feed elevator

- Vertical tank

- Tubular conveyor

- Horizontal tank

- Bucket elevator

- Flexible elevator

- Height-adjustable elevator

- Fruit conveyor

- Vertical bucket elevator

- Feed-mill unit

- Pneumatic conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.