- Products

- Catalogs

- News & Trends

- Exhibitions

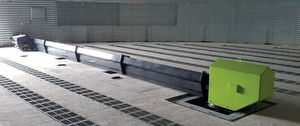

Grain sweep auger L DSM for silos

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for grain, for silos

Description

The L DSM is the only sweepauger model which truly does not require the use of intermediate emptying outlets to start and therefore protects the silo from any unbalance due to accidental off-centre emptying.

The thrust power of the sweepauger and the angle of attack of the screw allows the L DSM sweeping auger to unload materials with large slope angles.

The use of two decoupled augers makes possible to install high powers on large diameter screws and to achieve very high discharge rate of 500TPH !

The 2 screws are coupled to parallel shaft geared motors located inside the silo.

A central geared motor is mounted on a ball bearing, while the second geared motor is located on the equipment frame.

Both gearmotors are connected to an electric rotary manifold for continuous rotation of the sweepauger around the silo.

The L DSM sweepauger has a small footprint in the tunnel.

The simple electromechanical design makes maintenance easier to tackle without high qualification for the customer maintenance team.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.