- Products

- Catalogs

- News & Trends

- Exhibitions

Fan for livestock buildings 81350 seriesdairy farmfor air circulationsuspended

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Application

- for livestock buildings, dairy farm

- Function

- for air circulation

- Installation

- suspended

- Other characteristic

- panel, double

- Diameter

1.1 m, 1.2 m, 1.4 m

(3'07" , 3'11" , 4'07" )- Air volume

25,000 m³/h, 30,000 m³/h, 35,000 m³/h

(882,866.7 ft³/h, 1,059,440 ft³/h, 1,236,013.3 ft³/h)- Power

400 W, 450 W, 550 W

Description

Premium Plastic Barn Fans for Superior Livestock Ventilation

- Our agricultural cooling fans utilize a unique suspended design with maintenance-free plastic housing. The stainless steel blades maintain perfect balance even at high speeds, while the magnesium-aluminum alloy motor ensures efficient heat dissipation. Safety protection grids prevent accidents, making these units ideal for dairy farms and beef facilities.

Plastic Cow Shed Fan for Livestock Ventilation

- If you’re looking for top–notch ventilation and cooling in cow sheds, our plastic cow shed fan is the perfect pick. It features a suspended design with a double–layer hollow plastic outer frame. This fan delivers excellent ventilation and cooling performance. Plus, it boasts a long service life, resists corrosion, and has insulating properties, making it safer to use.

Product Introduction

- Our plastic cow shed fan is built for optimal airflow in cow housing. The double–layer hollow outer frame, made from plastic, ensures durability and efficient heat dissipation. It’s designed to hang, saving space while providing widespread air circulation. Whether for a small farm or a large dairy operation, this fan meets ventilation needs.

Product Specifications

- Model: 813501, 813502, 813503

- Size (mm): 1140 x 1140, 1240 x 1240, 1380 x 1380

- Number of Blades (piece): 4, 5

- Rated Voltage (V): 380V

- Input Power (W): 400W, 450W, 550W

- Air Volume (m³/h): ≥25000, ≥30000, ≥35000

- Noise (db): ≤70

Product Features

- Durable Outer Frame: Made of polyethylene, the double–layer hollow outer frame is formed via rotational molding in one go. It’s tough and long–lasting.

- High–Quality Blades: Blades are crafted from premium stainless steel. They use laser cutting and stamping processes. They offer large air volume, won’t deform or break, don’t collect dust, and look great while being durable.

- Efficient Motor: The motor has an aluminum–magnesium alloy shell. It dissipates heat well and works efficiently.

- Safety Protection: A safety guard is installed on the front of the fan to protect the blades during operation.

- Stable Operation: The entire fan is calibrated with a computer dynamic balance tester. It runs smoothly, has low noise, good stability, and a long service life.

Installation

- First, find a suitable spot in the cow shed to hang the fan. Make sure the mounting area is sturdy. Then, use the proper hardware to secure the fan in place. Connect the fan to the 380V power supply as per the instructions. Finally, test the fan to ensure it runs smoothly.

Maintenance

- Regularly clean the fan blades and outer frame to remove dust and debris. Check the motor for overheating or unusual noises. Inspect the safety guard to ensure it’s intact. Lubricate the motor bearings as needed. If any parts show signs of wear, replace them promptly to keep the fan working well.

Key Specifications:

- Models: 813501, 813502, 813503

- Sizes: 1140x1140 mm, 1240x1240 mm, 1380x1380 mm

- Number of Blades: 4 or 5

- Rated Voltage: 380V

- Input Power: 400W, 450W, 550W

- Air Volume: ≥25000, ≥30000, ≥35000 m³/h

- Noise: ≤70 db

- Frame Material: Polyethylene, double-layer hollow, rotational molding

- Blade Material: Stainless steel, laser cut and stamped

- Motor: Aluminum-magnesium alloy shell

- Safety: Front safety guard

- Mounting: Hanging/suspended

Related Searches

- Air circulation fan

- Farm building fan

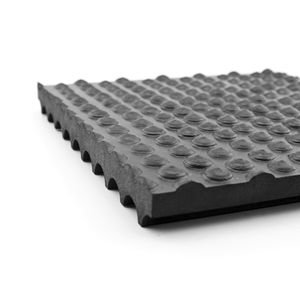

- Slatted floor

- Fan for livestock buildings

- Wall-mounted fan

- Non-slip flooring

- Rubber flooring

- Greenhouse fan

- Extraction fan

- Rubber floor mat

- Slatted floor for farm buildings

- Plastic flooring

- Galvanised steel fan

- Pig breeding slatted floor

- Non-slip floor mat

- Panel fan

- Plastic slatted floor

- Evaporative cooling pad

- Suspended fan

- Non-slip slatted floor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.