- Products

- Catalogs

- News & Trends

- Exhibitions

Greenhouse fan 81140 seriesfarm buildingfor livestock buildingsextraction

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Application

- farm building, for livestock buildings, for greenhouse

- Function

- extraction

- Installation

- wall-mounted

- Other characteristic

- galvanised steel

- Diameter

910 mm, 1,270 mm

(35.8 in, 50 in)- Air volume

21,000 m³/h, 40,500 m³/h

(741,608 ft³/h, 1,430,244 ft³/h)- Power

550 W, 1,100 W

Description

Box – type Exhaust Fan: Your Ideal Ventilation Solution

The Box Exhaust Fan provides professional-grade air exchange for livestock buildings, greenhouse operations, and commercial farming facilities. Engineered for continuous duty, these agricultural exhaust fans move between 21,000-40,500 m³/h depending on model size. The heavy-gauge zinc coating (275g/m²) offers superior protection against ammonia corrosion in poultry houses and swine facilities.

Heavy-Duty Box Exhaust Fan for Agricultural Ventilation

When it comes to ventilation in livestock farming and greenhouse environments, the Box – type Exhaust Fan stands out as a reliable choice. This fan is specifically engineered to meet the ventilation needs of these specialized settings, ensuring a fresh and healthy atmosphere. Its unique design and robust construction make it a top-notch option for those seeking efficient air-exchange solutions.

Product Overview

Our Box – type Exhaust Fan is crafted with precision. The outer frame is manufactured using advanced CNC equipment processing technology, guaranteeing high quality and durability. The distinctive push–pull opening structure enables the shutters to open and close smoothly, facilitating seamless ventilation control.

Technical Specifications

- Product No.: 811405, 811407

- Blade Diameter: 1270 mm (50″), 910 mm (36″)

- Blade Speed: 440 rpm, 650 rpm

- Motor Speed: 1400 rpm

- Airflow: 40500 m³/h, 21000 m³/h

- Noise: ≤70 dB

- Power: 1100 W, 550 W

- Voltage: 380 V

- Height: 1380 mm, 1000 mm

- Width: 1380 mm, 1000 mm

- Depth: 450 mm

- Frame: 275g/m² galvanized steel

- Blades: One-piece stamped stainless steel

- Opening Device: High-strength nylon

- Carrying Handle: Recessed design

Key Features

- Corrosion–Resistant Frame: The outer frame of the fan is made from 275–gram galvanized layer steel plate. This material offers excellent corrosion resistance, significantly extending the fan’s service life.

- High–Quality Blades: The fan blades are formed by one–piece stamping of high–quality stainless steel. They are not only rust–proof but also aesthetically pleasing.

- Sturdy Opening Device: The push–pull opening device is processed from high–strength nylon, ensuring high strength and long–lasting durability.

- Convenient Handling Design: The recessed carrying handle design makes the loading, unloading, and transportation of the fan extremely convenient.

Installation Process

Mount the unit vertically on walls or ventilation openings using corrosion-resistant fasteners. Maintain 50cm clearance from obstructions for optimal performance. The symmetrical frame allows horizontal or vertical mounting. Connect to three-phase power following local electrical codes. Test louver operation before final commissioning.

Maintenance Guidelines

Wipe down blades seasonally with non-abrasive cleaners. Inspect nylon slides biannually for smooth movement. Tighten mounting bolts during deep cleaning periods. No lubrication required for stainless steel components. Replace louver seals every 3-5 years depending on usage intensity.

Related Searches

- Air circulation fan

- Farm building fan

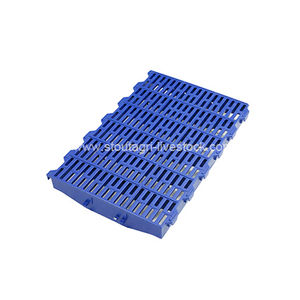

- Slatted floor

- Fan for livestock buildings

- Wall-mounted fan

- Non-slip flooring

- Rubber flooring

- Greenhouse fan

- Extraction fan

- Rubber floor mat

- Slatted floor for farm buildings

- Plastic flooring

- Galvanised steel fan

- Pig breeding slatted floor

- Non-slip floor mat

- Panel fan

- Plastic slatted floor

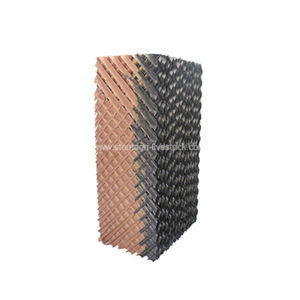

- Evaporative cooling pad

- Suspended fan

- Non-slip slatted floor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.