- Wear and Spare Parts

- Towing & Transmissions

- Metal shock absorber

- Jäger Gummi und Kunststoff GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

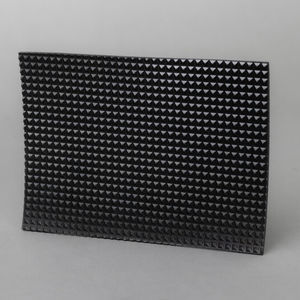

Vibration shock absorber rubbermetal

Add to favorites

Compare this product

Characteristics

- Function

- vibration

- Material

- metal, rubber

Description

Standardized, or specially adapted to your requirements. Rubber-metal elements are essential for the production of vibration dampers, stop and rubber buffers, machine feet and other rubber-metal products. Vibration damping and noise reduction. They are used in the automotive industry, mechanical engineering and construction for vibration damping and noise reduction and construction to extend the service life of parts and components and increase comfort.

Quickfacts Rubber-Metal Elements

Application - Storage, decoupling, damping

Materials - NR, IIR but also e.g. EPDM, NBR, silicone, etc.

Hardness - soft (approx. 40-45 ±5 Shore A), medium (approx. 50-55 ±5 Shore A), hard (approx. 65 -70 ±5 Shore A)

Quality - Megi® & Schwingmetall®, but also alternative qualities

Standard rubber-metal buffer - Versions: A, B, C, D, E - further versions e.g. AT = "waisted", AP = "parabolic", K = "conical", S = "with bead"

Further products - Ring buffers, conical bearings, rubber-metal rails, stop rails, U-rails, machine feet (height-adjustable, with or without breakaway protection), torsion bushings, rubber-metal hat elements, hydromounts, rubber-metal bushings, pot elements, etc.

Color - Standard: black, other colors on request

Areas of application

Rubber-metal elements combine vibration isolation, shock absorption, noise damping or buffering through the solid product combination of rubber and metal. These maintenance-free, easy-to-install components provide impressive damping, cushioning and suspension. As your partner, we offer you a broad standard range as well as customized solutions for areas such as:

Commercial vehicles such as excavators and cranes are central to construction.

Other Jäger Gummi und Kunststoff GmbH products

Material Combination

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.